There exists a approach that may be used for recalibrating a Device and it is named bench calibration. It truly is an important process that needs to be executed so as making sure that all of the parts of a Device are working thoroughly. If a Instrument is not really effectively re calibrated, it can cause inaccurate measurement. This can result in a variety of troubles.

Essential method

There are various steps linked to the whole process of recalibrating a Resource. Calibration entails evaluating an instrument's output which has a reference instrument's. This comparison permits the measuring instrument to provide additional exact results.

The most elementary method is to employ a set of Qualified gages blocks. These are frequently designed to nationwide criteria. In general, they've got a thickness of 1 mm along with a diameter of sixty three mm.

Using these gages, you should evaluate a range of loads. Typically, you will have 5 to ten test details. One example is, you could possibly measure displacement, interior tension, and corner radius.

Throughout calibration, you should record the result to assist you to identify how to proceed next. You can also make use of automated workflows to retrieve and review details.

To achieve this, You'll need a good calibration program. A nicely-published system will make clear the ways involved with the calibration system. It will eventually include the efficiency technical specs you will use, the techniques and tools utilised, and The explanations for that calibration.

Accreditation

For anyone who is Doing the job to make high quality products, you'll need to calibrate your equipment. This method is necessary to ensure the precision of your products and solutions and processes. You need to use a Qualified calibration services provider to satisfy your prerequisites.

Accredited laboratories show their specialized and testing competence. Accreditation also offers assurance that the lab has actually been independently confirmed by a 3rd party.

The scope of accreditation defines the parts of the laboratory and the kinds of measurements it is actually EML Calibration able to performing. Additionally, it describes the type of apparatus that's utilized. An accrediting physique will generally assess the quality of a lab's ecosystem and staff.

The calibration laboratory is predicted to abide by a stringent set of specifications. These contain the security with the personnel as well as surroundings. A chance administration technique is usually needed.

ISO/IEC/EN 17025 is a world conventional for good quality. It requires a risk management system and an intensive audit of your lab. In addition, the calibration laboratory is needed to have an excellent assurance method.

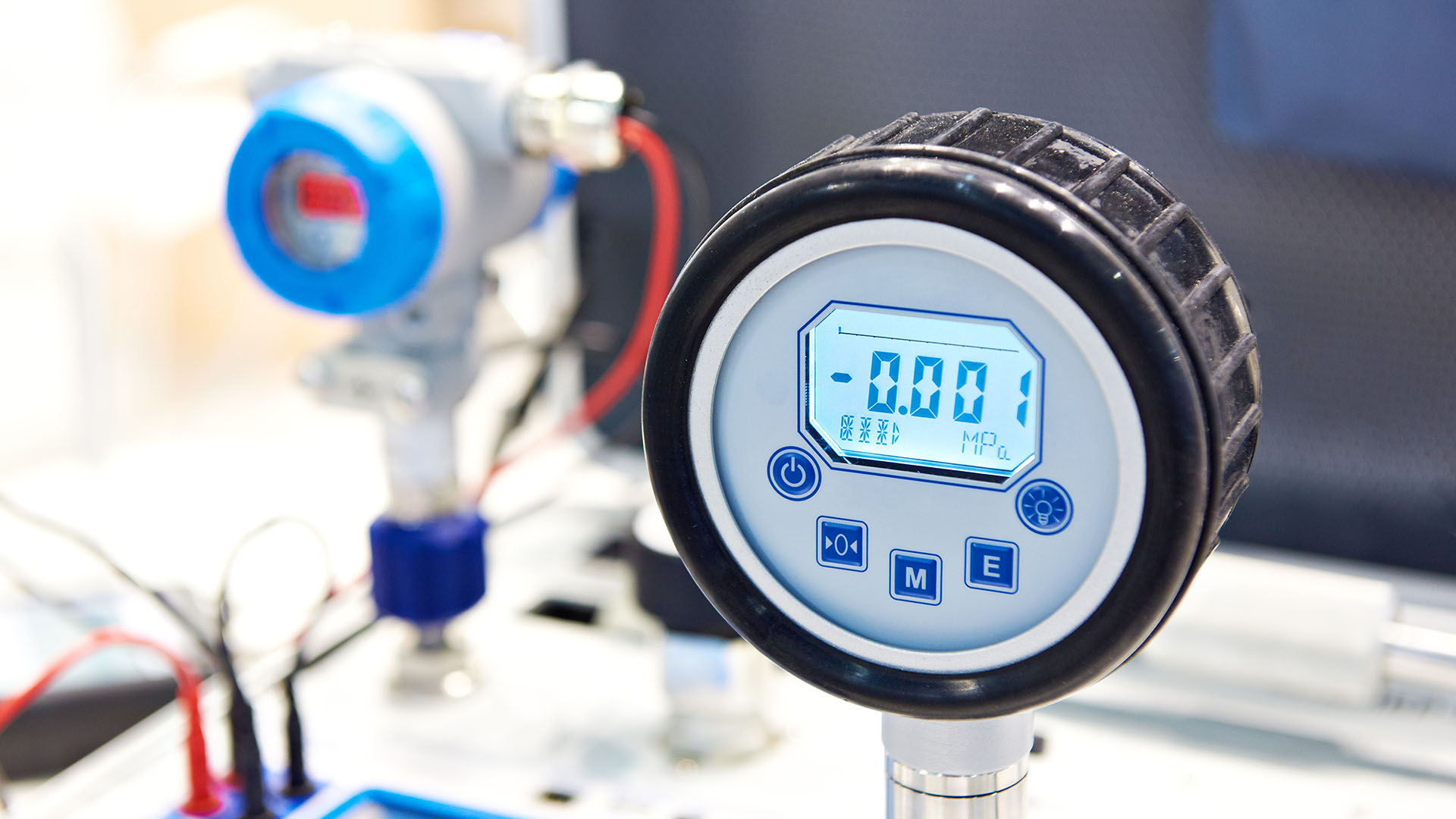

Bench calibration

When your bench calibration Instrument has to be recalibrated, it is necessary to understand how to effectively complete the process. This can be certain that the measurement is traceable into the National Institute of Specifications and Technologies (NIST) typical.

Calibration is the initial step to retaining the functionality of the measurement equipment. It is usually the sole way to guarantee the precision of the devices.

Bench calibration will involve disconnecting your instrument from the method it really is measuring, cleaning it, after which you can mounting it with a exam stand. For being efficient, the process should be carried out within a managed natural environment.

A controlled surroundings helps to reduce the total uncertainty and the potential risk of glitches. The bench ought to have access to a strain resource. Generally, this is the hand pump. On top of that, the gauge ought to be mounted in the exact same orientation as the method.

In order to effectively calibrate your bench scale, You will need a reference tension gauge that could be traced back to your manufacturer. Generally, you can hope the traceable strain reference to own an accuracy of four situations the accuracy of the machine.

Traceability

Traceability is the entire process of connecting the outcome of a calibration into the established expectations. This can be a way to attenuate risk related to measurement machines along with the devices accustomed to evaluate.

The National Institute of Benchmarks and Technology (NIST) has actually been producing technical information on traceability. NIST also provides certifications for reference elements and measurement protocols. What's more, it conducts coordinated outreach systems on traceability.

The NIST Top quality Technique for Measurement Services defines traceability as being the relationship amongst the http://www.thefreedictionary.com/calibration measurements and final results of a calibration as well as the established criteria. If the measurements are for being traced to NIST or to a special normal, the Group ought to observe check techniques and protocol.

Traceability is usually a prerequisite to meeting the requirements of globally regulatory agencies. A very good merchandise might be worthless if it has no assurance of correct measurement. Moreover, it may trigger hefty expenditures if it fails.

The initial step in traceability is to establish a sequence of reference. Using the International Process of Units, or SI, a Device have to be calibrated and its final results are then confirmed and acknowledged.